At Dispomed, we are always on the lookout for innovative solutions that enhance the efficiency and safety of veterinary clinics. We are thrilled to introduce our latest offering, the V10 Air Plasma Sterilizer by Plasma Bionics—a game-changer in the world of sterilization. With its advanced plasma technology, the V10 offers unmatched performance while ensuring a safer and more sustainable sterilization process.

Key Benefits of the V10 Air Plasma Sterilizer

-

Chemical-Free Sterilization:

The V10 uses low-temperature air plasma technology, which eliminates the need for harmful chemicals like ethylene oxide. This ensures a safer environment for your team and your patients while also being eco-friendly. -

Versatile Sterilization for Veterinary Clinics:

This sterilizer has been extensively tested with a variety of materials commonly used in veterinary practices, including metals, polymers, glass, and plastics, ensuring its suitability for a broad range of applications. -

Fast Sterilization Cycles:

With a typical cycle time of 4 hours, the V10 minimizes downtime and maximizes productivity. This rapid process ensures that your instruments are ready when you need them, improving your clinic’s workflow. -

Highly Effective Sterilization:

Plasma Bionics' advanced technology penetrates deeply, effectively sterilizing even hard-to-reach areas. Independent laboratory testing has proven the V10’s capability to achieve a 6-log (99.9999%) microbial reduction, including spores. -

Cost-Effective and Low-Maintenance:

The V10's sterilization process eliminates the need for consumables, such as sterilization wraps or chemical indicators, reducing operational costs. Additionally, the system is designed for long-term reliability with minimal maintenance. -

User-Friendly Interface:

With its intuitive touch-screen display, the V10 makes sterilization as easy as possible. The built-in self-diagnostics and operational status updates ensure you are always informed of the machine’s performance.

What Is Air Plasma Sterilization®?

Air Plasma Sterilization® is a proprietary term coined by Plasma Bionics to differentiate its non-thermal plasma (cold plasma) technology from other sterilization systems that rely on gas or vapor. Plasma, in this context, refers to ionized gas, the fourth and most energized state of matter. In the V10, air composed of approximately 78% nitrogen (N2), 20% oxygen (O2), and other trace gases is ionized to form a powerful sterilant.

When plasma is generated inside the sterilization chamber, the ionized gases create reactive oxygen and nitrogen species that rapidly destroy microorganisms on the surfaces of veterinary instruments. This advanced system provides a multi-faceted approach for efficiently eliminating pathogens while remaining safe for heat-sensitive materials.

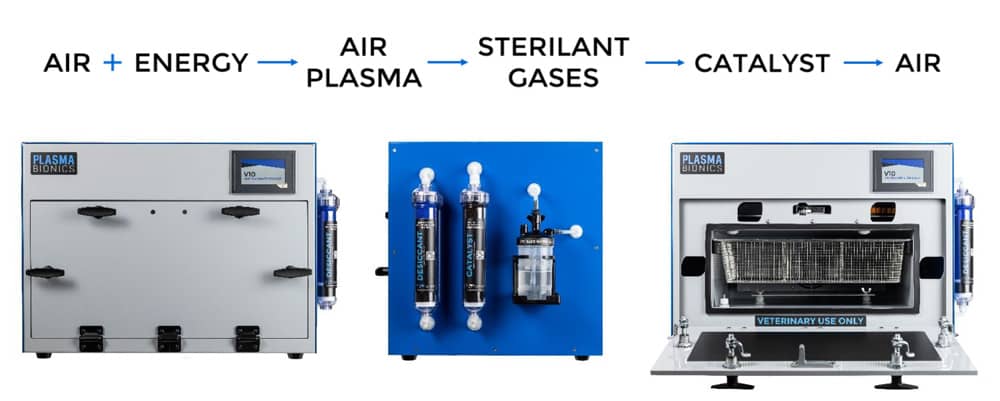

How Does Air Plasma Sterilization® Work?

The Air Plasma Sterilization® process relies on the generation of highly reactive oxygen and nitrogen species, which cause oxidative damage to microorganisms. This natural oxidation process is an extremely efficient way to eliminate bacteria, viruses, and spores. The V10’s plasma sheets produce ions, charged particles, and reactive oxygen species (like ozone, nitrogen dioxide, hydroxyl radicals, and nitric oxide) that break down microbial structures and DNA, providing a robust sterilization process.

After the sterilization cycle, the gases are converted back into air, leaving no harmful byproducts and requiring no additional ventilation systems, making it an environmentally friendly solution.

The Air Plasma Sterilization Cycle

- Preconditioning:

The air inside the sterilization chamber is conditioned to specific pressure, temperature, and humidity levels to ensure reliable performance, regardless of geographic location or environmental conditions. - Sterilizing:

Plasma is generated within the sterilization chamber, creating a variety of reactive oxygen and nitrogen species that destroy microorganisms. The cycle time is designed to ensure a sterility assurance level (SAL) of 10^-6, meaning a one-in-a-million chance that a microorganism survives. - Ventilating:

After sterilization, the reactive gases are passed through a catalyst, converting them back into air, ensuring the sterilization process is both safe and eco-friendly.

Why Choose Air Plasma Sterilization®?

The Air Plasma Sterilization® process offers numerous advantages over traditional sterilization methods:

- Low Temperature:

Sterilization occurs at 40°C (104°F), protecting heat-sensitive instruments from damage. - Low Pressure:

The process occurs at near atmospheric pressure, ensuring delicate instruments aren’t subjected to extreme forces. - Low Cost per Cycle:

With a cost per cycle ranging between $3 and $5, the V10 offers significant savings over other sterilization systems. - No Chemical Consumables:

Air and electricity are the only inputs required, making it an environmentally friendly and cost-effective option. - Broad Material Compatibility:

Compatible with a wide range of plastics, elastomers, and medical-grade metals, the V10 is suitable for almost any veterinary instrument. - Minimal Maintenance:

The sterilizer only requires simple cleaning every 15 cycles, and consumables like the plasma sheets have an indefinite shelf life.

Safety and Efficiency in One Device

The V10 Air Plasma Sterilizer’s advanced technology is a perfect fit for veterinary clinics aiming for both maximum sterilization efficiency and uncompromised safety. It works without leaving harmful residues, making it an excellent choice for practices that prioritize the well-being of both animals and staff.

Interested in Learning More?

Contact your Dispomed representative today to learn how quickly the Plasma Bionics V10 can provide a strong return on investment for your clinic, or visit our product page for further details.