To optimize the life of your handpieces, it is essential to lubricate them meticulously.

Indeed, if the manufacturer’s lubrication recommendations were not respected and there is breakage, it will not be covered under warranty.

Have a look at our handpiece lubrication tips to avoid any breakage.

See the difference between a properly lubricated turbine vs a turbine with a lack of lubrication

Lubricate every use

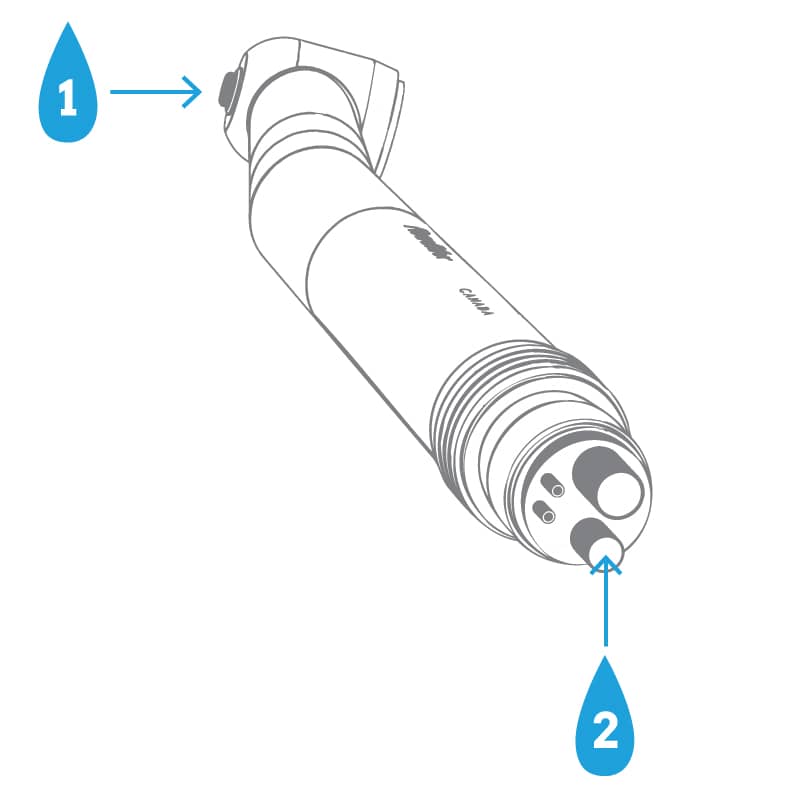

High-speed

1. Drops of oil here – daily.

2. Drops of oil here – before and after autoclaving cycle (or according to manufacture). Lubricate the high-speed handpieces daily on the smaller of the two large holes.

3. Oil after every 15 minutes of use.

4. Do not leave levers open.

5. Daily lubricate chuck.

Low-speed

1. Drops of oil at these two places – each use.

2. The low-speed handpiece can be broken down into three parts. Disassemble the three parts;

3. Lubricate both ends of the contra-angle.

4. Lubricate the prophy angle.

5. Re-assemble the handpiece.

For both high and low-speed handpieces lubrication;

For drop oil, with the bur inserted (for the high-speed), place lubricant (2-3 drops) into the air intake, run and purge unit for 20 seconds, or until all excess oil is expelled.

For aerosol oil, with the bur inserted (for the high-speed), spray lubricant for 1 second into the air intake and run on purge unit for 20 seconds, or until all excess oil is expelled.

If expelled oil is colored, repeat the lubrification process until expelled oil is clear.

Tips

+ Remove the burs and other attachments (never sterilize with attachment).

+ Lever-operated chucks must be closed.

+ Never cool a hot handpiece under cold water or by placing it in a refrigerator.

+ Allow drying cycle to complete before removing handpiece from the autoclave to ensure that all moisture has been removed.

+ Make sure the handpiece is completely cool and dry before operating.

+ Have autoclave unit serviced regularly by manufacturer’s representative.

+ Do not cheat the bur this will damage the chuck.

+ Do not use pliers to remove burs.

+ Use a proper oil adaptor for your aerosol can.

+ Set air pressure according to manufacture (usually between 30-40 psi).

Is your dental unit due

for preventive maintenance?

Contact our team of dispatchers to schedule your maintenance!

Start using your unit with good maintenance habits. Let’s give yourself relief and avoid stress by subscribing to our automated maintenance reminders. We will be guiding you in using the unit to its full potential and optimizing its operating service time.

Download our Veterinary Dental Checklist Now!

To help you stay ahead, we’ve developed a Veterinary Dental Equipment Checklist. This essential resource ensures that your clinic is fully equipped to meet the highest standards of care and efficiency in dental procedures.

Related Products

-

tvet 10M Manual Autoclave

-

Sable EZ Lube Dropper

-

Round Bur, size 4, 16 mm

-

Round Bur, size 1/4, 16 mm

-

HIGHDENT Dental LED High Speed Turbine Handpiece

-

HIGHDENT Dental High Speed Turbine Handpiece

-

Flame Shape short, diamond (fine grit) Bur, size 5, 19 mm

-

Feline Bur Set

-

Canine Bur Set

-

6-hole quick connector with LED turbine

-

4-hole quick connector turbine